Q : 'Can the Hals Icelandic furnace build be re-used after three winters of weathering?

Well - kind of...

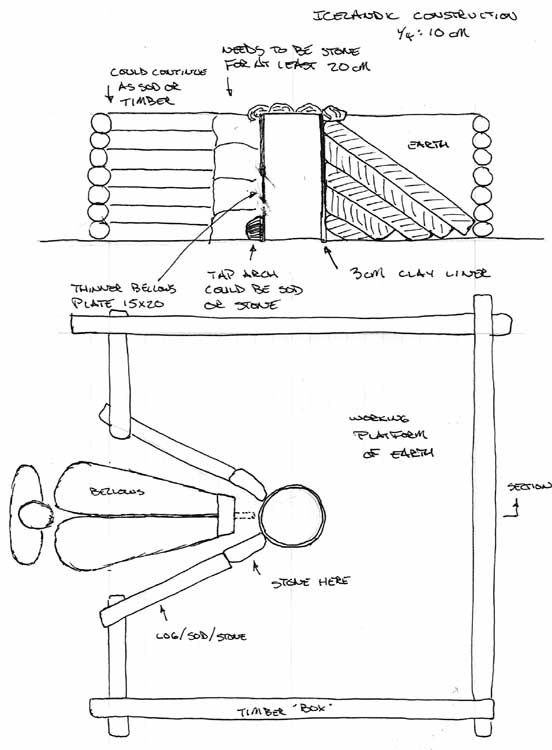

In consideration of the upcoming November 3 (Sunday) bloomery iron smelt at Wareham, Neil Peterson and I decided to return to the 2021 furnace that was a full build of the sod cone with thin clay lining as used at Hals, Iceland. This furnace had suffered considerble damage from both the extraction process and the intervention of a snapping turtle (!) after the June smelt that year. The front section was repaired and it was fired again in September. At that point major cracking resulted in the failure of the front wall section, with a wide band of loosely fused dirt in that area. (see https://warehamforgeblog.blogspot.com/2021/09/replacements-and-improvements-smelter.html )

The structure has been exposed to the weather since that point. Rain had washed loose earth into the interior and out the open front, and caused the supporting sods to slump down. Freeze and thaw had eroded the upper portions of the fused clay liner, and widened many cracks. The still mainly intact liner had slumped forward through about 25 degrees off vertical.

The remains of the furnace, wild grasses trimmed off the sod cone. Front extraction side forward

Stick follows the line of the inner furnace surface.

Cracked and flaked away surface of the upper portions visible

Neil Peterson and I attempted to dig it clear of collapsed soil and set it back to vertical yesterday.

Not so much! The fractured liner broke into two larger and a number of smaller pieces

Broken after our attempt to straighten the liner, the two larger pieces each about 1/4 of the original.

Working on the impression that will little clay available, Icelanders would attempt to keep what they had and patch it back together (??) this is what we did.

The missing front section was replaced with on hand stone blocks, setting a ceramic tube tuyere. The previously used basalt lintel stone was set above this to support the upper blocks. From the tuyere line upwards gaps between the blocks were sealed with fresh clay.

As much as possible, remaining pieces of the fused inner liner were patched together, gaps and cracks sealed with fresh clay. The clay used is the Icelandic clay analog mix, based on samples obtained by Michelle Hayure-Smith, and suggested by team member Marcus Burnam (see https://warehamforgeblog.blogspot.com/2021/06/sticking-to-it-clay-mix-for-icelandic.html) A very rough calculation was made of the clay required = about 2.5 litres (as a plastic mix).

Image into the interior, showing the lower rear and left side surfaces. Fresh clay is dark grey.

Two wooden sticks were driven down to help support the wall pieces as they were sealed in with fresh clay. It is expected there will be further cracking between the old and new surfaces as that applied clay dries and shrinks. There should be a second repair made to ensure new cracks are sealed before firing. This was a step not taken between the previous two uses, thought to be why there was a major burn through in that earlier front wall section repair.

A circle of stone blocks was added around the top of the opening to even off the shaft. These supported by additional cut sod. As currently set, the furnace has a roughly oval interior, about 30 cm front to back and 35 cm side to side. Total shaft height is irregular at 55 - 60 cm. The tuyere is set about 15 cm above the dirt base (which could be dug lower). This creates a shaft height of 40 - 45 cm.