Over the years many people have been frustrated by the concept of 'intensity' on the glass beads page. The page, and all of the bead charts have now been updated to reflect the actual numbers of the beads. A few new thoughts and ways of looking at the beads have also been added.

Have a look and let us know what you think!

http://www.darkcompany.ca/beads/beads.php

skip to main |

skip to sidebar

One of the recurring problems the DARC bead making team has experienced is ash scars on the beads we make with various Viking Age type bead furnaces.

If readers are not familiar, you should spend a bit of time over on the main DARC web site - the area detailing our ongoing experimentation into Norse glass bead production :

http://www.darkcompany.ca/beads/index.php

It should be noted that Neil Peterson is the primary lead on this experimental archaeology project. (I only contribute as the 'fire guy', primarily on furnace design, with at least a basic level of skill with glass bead making itself)

As a (very!) brief overview :

• Plentiful archaeological remains at several Viking Age trade centre / town sites show that the Norse certainly made glass beads.

• 'Waste' remains do hint at some of the possible methods used to make individual beads.

• Raw glass itself does seem to be an imported material.

However :

• Artifact remains are almost entirely limited to completed beads (graves) or waste products.

• There are only a very few actual glass bead making * tools * that have been recovered.

• There are no compete bead making furnaces. All that have been found are a very few clay 'bases' - that may (or may not!) suggest possible furnace dimensions.

All this, as practical workers, leaves us with a huge number of unanswered questions. (Summary of 'Questions & Answers' by Neil )

The experimental series has mainly concentrated on a couple of primary concerns:

• How do you build and operate a small charcoal fired furnace that allows you to effectively make beads similar to the ones known from the Viking Age?

• What is the superstructure for that kind of furnace - as defined by the remaining 'base plates'?

I have commented before concerning possible *effective* furnace design. (Admittedly, these based on my understanding of iron smelting furnaces and charcoal blacksmith forges.) :

the ash produced ?

A given volume / mass of charcoal will produce a fixed amount of ash.

This will be a variable related I suspect most directly to wood type.

It may be effected by available air supply. (ie complete vs incomplete combustion)

It may be effected by actual temperature inside the furnace.

Wiki gives : "Typically between 0.43 and 1.82 percent of the mass of burned wood (dry basis

Given that in our case the wood type is not highly variable (usually oak or maple, standard sources).

The volume of the furnace is fixed (although changes between builds)

We are attempting to maximize temperature - kind of. Here we are balancing between duration and a fixed high temperature. To date we have been adjusting air volume to create what we consider an optimal temperature - of the exhaust gas (not necessarily the core burning temperatures, which I am not sure have been measured?)

So - we have an element to consider, which is particles over time.

1 kg charcoal yields 10 gm of ash (WAG) / complete burn time

Divide that by limited time that it takes to make a bead.

More important here is 'lofting' - how much ash is lifted into the expelled gases.

Generally we should have air input = gas output. (Scientifically there is some waggle here, based on relative volume of the elements in air against elements in the hot gas. I would think that not significant!)

Not *all* the ash produced is lofted. Much is trapped inside the remaining pile of charcoal inside the furnace.

This is especially true if there is a volume of 'non reacting' charcoal above the burning zone. This will be acting somewhat as a filter to trap particles.

Honestly, I think this is likely the major consideration. Bench test - compare ash visible in exhaust between start and end of a load cycle. Comparison test - how much ash is expelled from a smelting furnace (with about 40 cm of charcoal 'filter' above the combustion area)

Design implication? Build furnaces with a larger 'reaction area' - basically increase the bottom chamber height. (I did notice most of the builds others did on Saturday were very low furnaces - I expect these will have short effective working cycles, need more frequent loading, result in more ash in the exhaust.)

The other possible effect would be ash expelled from the reaction area, but because of height of the chimney below the working area for bead making, ash can settle back down into the chamber.

The core idea here is possibly increasing the chimney height.

I'm not so sure about this, as the ash particles are extremely light - and the air flow input is likely more than enough pressure / volume to still lift those a long way.

Increasing the distance or the complexity of the pathway of exhaust gas on its way out of the furnace may present a solution. The core problem here is doing this without loosing so much heat that the exhaust temperature drops below our needs.

The simplest way to construct a 'long chimney' would be with a tall, cylindrical furnace.

Primary problem is heat loss. There is the surface area (radiation loss) over internal volume ratio problem.

You might also use an internal set of baffels. This would in effect create an upper chamber with the

baffels above a lower chamber which in effect becomes a fire box. The upper chamber would suffer less heat loss - especially since one surface would be directly above the burning charcoal.

Primary problem here is complexity of construction.

In either case, one other consideration might be the air source. I'm not sure we are getting the correct balance between force and volume. Again our historic use is via a blacksmith's (speculative) equipment. I have certainly noticed massive variations in force and regularity of stroke between users. I think this is significant in terms of ash movement. What you desire is a slow, extremely even blow of constant pressure. It may be that a bag as a kind of regulator might be indicated.

It also would be valuable to have measurements 'in line' for air volume and pressure.

I would also suggest that input air from mechanical sources be controlled via an electrical controller (light dimmer) or a sliding gate of some. Both with markings at least relative - and repeatable.

What I meant about 'chimney shape not mattering' was an oversimplification and short form. I think the elements given above are much more significant. There are theoretical considerations on shape (round / square) that likely do not come into play on this scale.

To my understanding, in large scale buildings, this is more to do with construction abilities than effects.

There is the 'passive draw' effect - which is a function of height, and does not apply here (scale again).

There will be some 'settling effect' - ash falling down after a certain distance. I think this also relates to reduced temperature due to cooling effects of the stack walls. Certainly NOT what we want here.

There is a 'lofting' effect - basically a tall stack distributes the same ash over a wider fall area (so reducing the individual point by point impact). Again not our concern.

We are more concerned with heat concentration - maintaining a specific temperature at the stack mouth. A much wider chimney opening would certainly reduce the amount of ash present at a specific point location inside that opening. It would also be spreading the available heat energy out - certainly not a desirable effect in this case.

Without guidance from archaeology, anything we do is so speculative anyway.

On Saturday August 4 and Sunday 5, Neil Peterson (of DARC) and myself will be demonstrating Norse glass bead making techniques. The presentation will run roughly 1 PM - 4 PM, as part of the activities inside the Earth, Air Celtic Festival in Goderich Ontario.

For information and directions to the Festival web site.

Neil and I will be actually continuing our experimental work with Viking Age charcoal fired glass furnaces, based on artifact evidence largely from Ribe, Denmark. This has been an ongoing research and practical skills development project largely under Neil's leadership.

This will be a departure from what you have seen me do at the Festival in the past. In previous years, I have been illustrating proven techniques, which often have a historic basis, but generally I have been using modern tools. The focus is often towards the production of a finished object.

Here the stress is on experimental archaeology. The methods, even the exact tools, used by ancient Norse bead makers are not well represented by artifacts. The furnaces are represented only by flat base plates, no intact upper portions have ever been found. There is a LOT of guess work and trial & error involved!

So come watch us work - its sure to be an adventure. New discoveries can be made at any time!

So come watch us work - its sure to be an adventure. New discoveries can be made at any time!

Showing posts with label glass. Show all posts

Showing posts with label glass. Show all posts

Monday, July 25, 2016

Sunday, June 19, 2016

Beads Update Coming

I was asked about updating the beads pages to use bead numbers instead of intensity. I have recently finished updating the spreadsheets involved. Now the fun comes in re-writing the glass bead page and doing the updated bead charts. Look for that in the next month or so.

Tuesday, September 8, 2015

Considering Ash in Bead Furnaces

One of the recurring problems the DARC bead making team has experienced is ash scars on the beads we make with various Viking Age type bead furnaces.

If readers are not familiar, you should spend a bit of time over on the main DARC web site - the area detailing our ongoing experimentation into Norse glass bead production :

http://www.darkcompany.ca/beads/index.php

It should be noted that Neil Peterson is the primary lead on this experimental archaeology project. (I only contribute as the 'fire guy', primarily on furnace design, with at least a basic level of skill with glass bead making itself)

As a (very!) brief overview :

• Plentiful archaeological remains at several Viking Age trade centre / town sites show that the Norse certainly made glass beads.

• 'Waste' remains do hint at some of the possible methods used to make individual beads.

• Raw glass itself does seem to be an imported material.

However :

• Artifact remains are almost entirely limited to completed beads (graves) or waste products.

• There are only a very few actual glass bead making * tools * that have been recovered.

• There are no compete bead making furnaces. All that have been found are a very few clay 'bases' - that may (or may not!) suggest possible furnace dimensions.

All this, as practical workers, leaves us with a huge number of unanswered questions. (Summary of 'Questions & Answers' by Neil )

The experimental series has mainly concentrated on a couple of primary concerns:

• How do you build and operate a small charcoal fired furnace that allows you to effectively make beads similar to the ones known from the Viking Age?

• What is the superstructure for that kind of furnace - as defined by the remaining 'base plates'?

I have commented before concerning possible *effective* furnace design. (Admittedly, these based on my understanding of iron smelting furnaces and charcoal blacksmith forges.) :

Wednesday, October 10, 2012

"Bottle" Bead Furnace

*******************

The following is taken from an ongoing conversation Neil and I have been having about furnace design with an eye to reducing ash scarring. (As further background, Neil is proposing a series of tests that will produced measurable records of ash loading in the working area of the furnace.)

On 31/08/15 2:26 PM, Neil Peterson wrote:

... In passing on Sat you mentioned that chimney shape shouldn't impact ash.You asked - much of this may be obvious to you

Would you care to elaborate? Feel free to suggest chimney ideas you think I should look into for this cycle.

the ash produced ?

A given volume / mass of charcoal will produce a fixed amount of ash.

This will be a variable related I suspect most directly to wood type.

It may be effected by available air supply. (ie complete vs incomplete combustion)

It may be effected by actual temperature inside the furnace.

Wiki gives : "Typically between 0.43 and 1.82 percent of the mass of burned wood (dry basis

Given that in our case the wood type is not highly variable (usually oak or maple, standard sources).

The volume of the furnace is fixed (although changes between builds)

We are attempting to maximize temperature - kind of. Here we are balancing between duration and a fixed high temperature. To date we have been adjusting air volume to create what we consider an optimal temperature - of the exhaust gas (not necessarily the core burning temperatures, which I am not sure have been measured?)

So - we have an element to consider, which is particles over time.

1 kg charcoal yields 10 gm of ash (WAG) / complete burn time

Divide that by limited time that it takes to make a bead.

More important here is 'lofting' - how much ash is lifted into the expelled gases.

Generally we should have air input = gas output. (Scientifically there is some waggle here, based on relative volume of the elements in air against elements in the hot gas. I would think that not significant!)

Not *all* the ash produced is lofted. Much is trapped inside the remaining pile of charcoal inside the furnace.

This is especially true if there is a volume of 'non reacting' charcoal above the burning zone. This will be acting somewhat as a filter to trap particles.

Honestly, I think this is likely the major consideration. Bench test - compare ash visible in exhaust between start and end of a load cycle. Comparison test - how much ash is expelled from a smelting furnace (with about 40 cm of charcoal 'filter' above the combustion area)

Design implication? Build furnaces with a larger 'reaction area' - basically increase the bottom chamber height. (I did notice most of the builds others did on Saturday were very low furnaces - I expect these will have short effective working cycles, need more frequent loading, result in more ash in the exhaust.)

The other possible effect would be ash expelled from the reaction area, but because of height of the chimney below the working area for bead making, ash can settle back down into the chamber.

The core idea here is possibly increasing the chimney height.

I'm not so sure about this, as the ash particles are extremely light - and the air flow input is likely more than enough pressure / volume to still lift those a long way.

Increasing the distance or the complexity of the pathway of exhaust gas on its way out of the furnace may present a solution. The core problem here is doing this without loosing so much heat that the exhaust temperature drops below our needs.

The simplest way to construct a 'long chimney' would be with a tall, cylindrical furnace.

Primary problem is heat loss. There is the surface area (radiation loss) over internal volume ratio problem.

You might also use an internal set of baffels. This would in effect create an upper chamber with the

baffels above a lower chamber which in effect becomes a fire box. The upper chamber would suffer less heat loss - especially since one surface would be directly above the burning charcoal.

Primary problem here is complexity of construction.

|

| Standard Bellows - actually based on that for Blacksmith's Forge. |

In either case, one other consideration might be the air source. I'm not sure we are getting the correct balance between force and volume. Again our historic use is via a blacksmith's (speculative) equipment. I have certainly noticed massive variations in force and regularity of stroke between users. I think this is significant in terms of ash movement. What you desire is a slow, extremely even blow of constant pressure. It may be that a bag as a kind of regulator might be indicated.

It also would be valuable to have measurements 'in line' for air volume and pressure.

I would also suggest that input air from mechanical sources be controlled via an electrical controller (light dimmer) or a sliding gate of some. Both with markings at least relative - and repeatable.

What I meant about 'chimney shape not mattering' was an oversimplification and short form. I think the elements given above are much more significant. There are theoretical considerations on shape (round / square) that likely do not come into play on this scale.

To my understanding, in large scale buildings, this is more to do with construction abilities than effects.

There is the 'passive draw' effect - which is a function of height, and does not apply here (scale again).

There will be some 'settling effect' - ash falling down after a certain distance. I think this also relates to reduced temperature due to cooling effects of the stack walls. Certainly NOT what we want here.

There is a 'lofting' effect - basically a tall stack distributes the same ash over a wider fall area (so reducing the individual point by point impact). Again not our concern.

We are more concerned with heat concentration - maintaining a specific temperature at the stack mouth. A much wider chimney opening would certainly reduce the amount of ash present at a specific point location inside that opening. It would also be spreading the available heat energy out - certainly not a desirable effect in this case.

Without guidance from archaeology, anything we do is so speculative anyway.

Monday, August 5, 2013

Glass bead making furnace at Goderich Celtic Music Festival - this weekend! Aug 10 and 11

Hey all,

We'll be back at the Goderich Celtic Music Festival to demonstrate the various techniques Neil and his crew have learned about making glass beads in a (possible) Viking Age glass bead furnace.

Come on out and say 'hi!'

See all the collected blogs about our glass research here.

And the main section on bead research on our website proper is here.

Karen

We'll be back at the Goderich Celtic Music Festival to demonstrate the various techniques Neil and his crew have learned about making glass beads in a (possible) Viking Age glass bead furnace.

Come on out and say 'hi!'

See all the collected blogs about our glass research here.

And the main section on bead research on our website proper is here.

Karen

Thursday, January 3, 2013

Period Specific Beads

A little while ago there was a request to add new charts to the bead page to show the 'diagnostic' beads. These are the beads that are found only in one time period (red star) or more than twice as often in this time period than any other (green star). These sorts of beads are excellent additions to a necklace or strand for tagging your presentation to a particular time period. A little time finally opened up and these four summary pages were added to the other bead charts to aid in your shopping trips.

Wednesday, October 10, 2012

"Bottle" Bead Furnace

For a number of reasons, Neil Peterson and I decided not to

mount an iron smelt over Thanksgiving weekend, but concentrated on the

VA glass bead making furnace research instead.

The initial experiments in this area were framed by the existing clay 'based plates' found at Ribe Denmark. It should be noted that although there is evidence of glass bead production at a couple of Norse trade / urban sites, there has not been a single complete furnace found. Experimental furnaces we have constructed using these artifact footprints have never been truly effective for actually making beads. There may be some other purpose for the clay slabs (?)

There were a number of continuing problems with the large oval furnaces, as suggested by the artifact bases :

1) Very short effective temperature cycles - in the range of 10 minutes

2) Side ports proved very difficult to work inside - limited space and heat onto hands

3) Top ports proved less than ideal - too large an area for effective control of glass

4) Continuing problems with ash coating surface of beads

5) Large internal volume required considerable charcoal expenditures to operate

6) The top ports were quite effected by any cross winds (operated outside)

Taking my experience with charcoal forge fires, and what we have learned from the much larger charcoal fired iron smelting furnaces, I had suggested this as a possible effective layout:

We tried out a couple of early versions of this system, back in 2009. These were abandoned, mainly because they do not conform to the known artifact 'bases'.

The concept here is that all the exhaust gasses are bottled up and forced out of a top vent hole, which in effect creates a working space much like a more modern torch flame.

Returning to this operating system, Neil constructed a new prototype, based some new observations and suggestions from me, back in mid September. This furnace had been air drying for several weeks. Sunday's workshop saw it fired and operated through several charging cycles:

There was no doubt that this new furnace was a massive improvement:

1) Effective operating cycle in the range of 75 minutes (!)

2) Higher working temperatures at the upper port

3) Narrow flame created more effective control of the glass itself

4) Ash greatly reduced (mostly absent)

5) Significantly lower charcoal consumption

6) 'Time per bead' rate greatly reduced

This all creates one of the classic problems in experimental archaeology : 'If you can't get the same results, you can't be doing the same thing they did' vs 'That certainly works - but it does not match the available artifact evidence'.

In the actual absence of any complete furnaces (or even upper fragments) from VA sites, my gut feeling is that the few surviving 'bases' may be from some other process entirely. Annealing pans is one possibility.

Our research and experimentation continues...

(duplicated from 'Hammered Out Bits')

The initial experiments in this area were framed by the existing clay 'based plates' found at Ribe Denmark. It should be noted that although there is evidence of glass bead production at a couple of Norse trade / urban sites, there has not been a single complete furnace found. Experimental furnaces we have constructed using these artifact footprints have never been truly effective for actually making beads. There may be some other purpose for the clay slabs (?)

There were a number of continuing problems with the large oval furnaces, as suggested by the artifact bases :

1) Very short effective temperature cycles - in the range of 10 minutes

2) Side ports proved very difficult to work inside - limited space and heat onto hands

3) Top ports proved less than ideal - too large an area for effective control of glass

4) Continuing problems with ash coating surface of beads

5) Large internal volume required considerable charcoal expenditures to operate

6) The top ports were quite effected by any cross winds (operated outside)

Taking my experience with charcoal forge fires, and what we have learned from the much larger charcoal fired iron smelting furnaces, I had suggested this as a possible effective layout:

We tried out a couple of early versions of this system, back in 2009. These were abandoned, mainly because they do not conform to the known artifact 'bases'.

The concept here is that all the exhaust gasses are bottled up and forced out of a top vent hole, which in effect creates a working space much like a more modern torch flame.

Returning to this operating system, Neil constructed a new prototype, based some new observations and suggestions from me, back in mid September. This furnace had been air drying for several weeks. Sunday's workshop saw it fired and operated through several charging cycles:

|

| Layout of the Furnace : about 30 cm OD. Annealing pot to left. |

|

| Lid removed, filling with charcoal. Electric blower used for this test series. |

|

| Fresh charcoal vents off combustible gasses for about 5 minutes. |

|

| Stable working flame, working a simple glass bead in the 'stack' |

|

| End of a working cycle, charcoal has burned away from centre to base. |

1) Effective operating cycle in the range of 75 minutes (!)

2) Higher working temperatures at the upper port

3) Narrow flame created more effective control of the glass itself

4) Ash greatly reduced (mostly absent)

5) Significantly lower charcoal consumption

6) 'Time per bead' rate greatly reduced

This all creates one of the classic problems in experimental archaeology : 'If you can't get the same results, you can't be doing the same thing they did' vs 'That certainly works - but it does not match the available artifact evidence'.

In the actual absence of any complete furnaces (or even upper fragments) from VA sites, my gut feeling is that the few surviving 'bases' may be from some other process entirely. Annealing pans is one possibility.

Our research and experimentation continues...

(duplicated from 'Hammered Out Bits')

Friday, October 5, 2012

Bead Furnace at Bonfield

(Cross posted from Hammered Out Bits )

These images are all by Vandy Simpson, taken at the Bonfield Battle event run each Labour Day by my old friend Steve Muhlberger.

As a continuation of the ongoing experimental research under Neil Peterson, DARC mounted a combination demonstration and hands on session with a possible Viking Age bead working furnace. The furnaces are clay & horse manure construction, fire charcoal, and are based on 'possible' footprints suggested by the archaeology primarily from Ribe Denmark. For a more complete background, see Neil's published research.

Two primary problems are plaguing us with this specific design, which is based on the size of one of the uncovered 'base plates' :

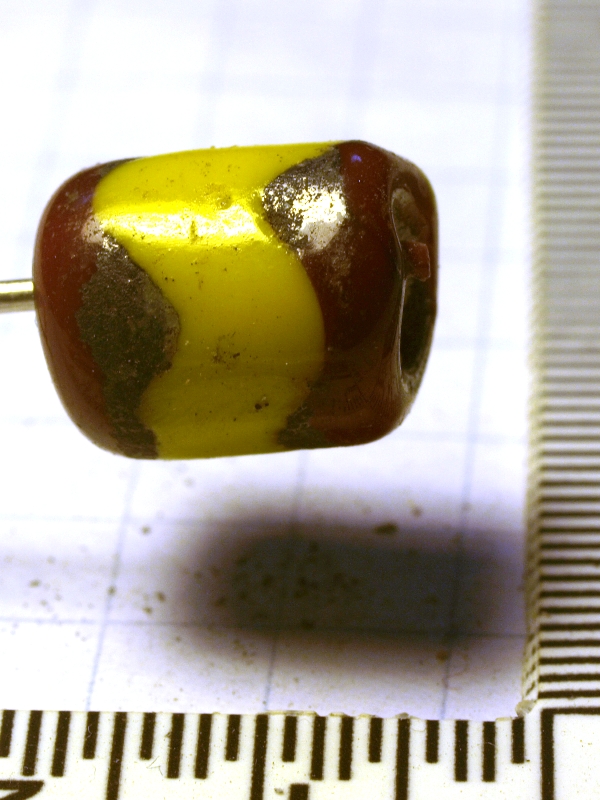

1) Although high enough temperatures can be produced to effectively work the glass, the actual effective time is quite short. Our skill levels are mid level at best, and typically only one semi complex (base plus two colour patterning) can be created in one charcoal fill cycle.

2) Marred surfaces, from flying ash and small particles of burning charcoal are common, almost universal. Artifact beads do not show these effects as common. This strongly suggests we are doing something 'wrong'.

Our next prototype furnace is abandoning the profiles suggested by the artifact bases. Instead I have suggested a design based more on the dynamics of burning charcoal, gathered from experience working with charcoal forges. The concept is to contain the hot gasses to produce an effect more like a torch - then work inside that blast. (An earlier post describes this system.)

There will be a workshop this weekend at Wareham where a few of us will be working with a new prototype. Hopefully there will be a field report with some images later in the week describing the results...

These images are all by Vandy Simpson, taken at the Bonfield Battle event run each Labour Day by my old friend Steve Muhlberger.

As a continuation of the ongoing experimental research under Neil Peterson, DARC mounted a combination demonstration and hands on session with a possible Viking Age bead working furnace. The furnaces are clay & horse manure construction, fire charcoal, and are based on 'possible' footprints suggested by the archaeology primarily from Ribe Denmark. For a more complete background, see Neil's published research.

|

| Overall view of the set up - inside the 'forge' duggout area |

|

| Working in the stack, heating new rod to apply decoration |

|

| Streaks are small pieces of burning charcoal in the vent |

Two primary problems are plaguing us with this specific design, which is based on the size of one of the uncovered 'base plates' :

1) Although high enough temperatures can be produced to effectively work the glass, the actual effective time is quite short. Our skill levels are mid level at best, and typically only one semi complex (base plus two colour patterning) can be created in one charcoal fill cycle.

2) Marred surfaces, from flying ash and small particles of burning charcoal are common, almost universal. Artifact beads do not show these effects as common. This strongly suggests we are doing something 'wrong'.

Our next prototype furnace is abandoning the profiles suggested by the artifact bases. Instead I have suggested a design based more on the dynamics of burning charcoal, gathered from experience working with charcoal forges. The concept is to contain the hot gasses to produce an effect more like a torch - then work inside that blast. (An earlier post describes this system.)

There will be a workshop this weekend at Wareham where a few of us will be working with a new prototype. Hopefully there will be a field report with some images later in the week describing the results...

Thursday, December 1, 2011

October Bead Experiments

On a miserable rainy weekend in Mid October the bead folks got together to run more furnaces to collect additional temperatures and make more beads.

The full report can be found at http://www.darkcompany.ca/beads/bead1011/

Interesting items in this report:

The full report can be found at http://www.darkcompany.ca/beads/bead1011/

Interesting items in this report:

- Temperatures were taken both inside and in the chimney at the same time for all three furnaces

- After the day was done the furnaces were broken down and the impact of the heat was recorded at many locations in the construction

- Some interesting beads were made

- Some interesting reticella was made

Now we just have a paper to write for ExArc

Thursday, November 17, 2011

More Bead Experiments

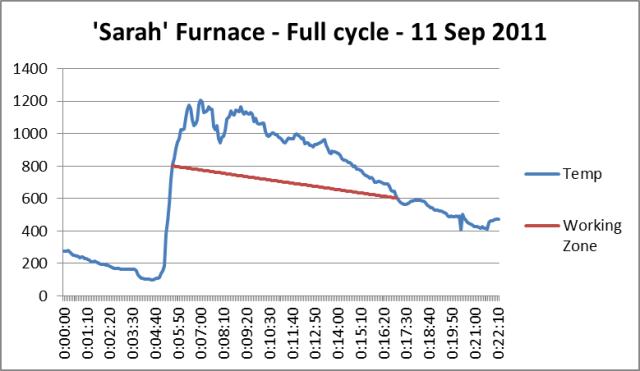

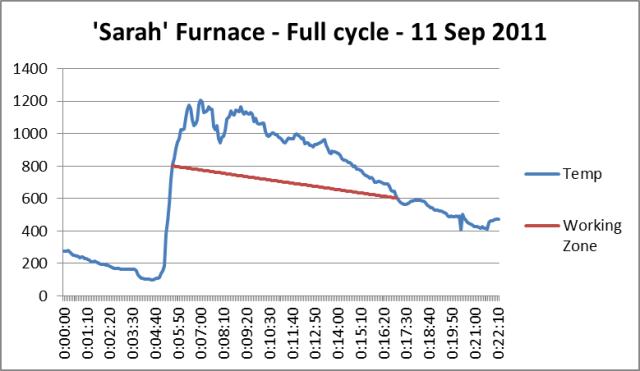

On Sept 10th the bead folks met again to make some beads and continue our research into the construction and use of the viking era furnaces.

In this case we were after data on how warm the furnaces got and how long they stayed at temperature. Peak temperatures around 1200 C were recorded and times in a useful temperature range ranged up to 10 minutes.

The full report can be found at

http://www.darkcompany.ca/beads/bead0911/

In this case we were after data on how warm the furnaces got and how long they stayed at temperature. Peak temperatures around 1200 C were recorded and times in a useful temperature range ranged up to 10 minutes.

The full report can be found at

http://www.darkcompany.ca/beads/bead0911/

Saturday, August 13, 2011

Glass Bead Furnace at Goderich Celtic

Cross posted from Darrell's Hammered Out Bits

As part of my nefarious plans * for the Earth, Air Celtic Festival at Goderich, this year's demonstration was of a Viking Age glass bead making furnace.

Now, this is really the research project of Neil Peterson, fellow member of DARC. Neil has driven the project, and has applied his (considerable) analytical powers to understanding the related archaeological remains. Much of our work has been focused on the remains from Ribe, Denmark. One of the problems is that the actual bead making furnaces are only represented by a number of clay base plates, with none of the upper portions of the furnaces surviving. There are plentiful examples of scrap and waste glass from the making process, as well as a large number of various styles of completed beads. As glass is virtually indestructible, glass beads are a common grave find as well.

My contribution to the beginning of the project was as the 'fire guy', lending my forge experience to the problem of how to construct and operate a charcoal burning glass furnace. It quickly was apparent to me that I needed some direct experience with how glass bead making works! To that end I assembled a basic set of modern lamp working tools and supplies, and made roughly 150 beads - just to get the hang of it.

Neil had made the furnace up a week before and allowed it to air dry. The construction is made of our standard 50 / 50 mix of powdered clay / shredded dry horse manure. The base oval is roughly 30 x 60 cm, and it stands about 30 cm tall. This is the ninth rendition of the basic plan, which at this point is close to an effective layout in terms of heat generation and functional spaces. (For some discussion of alternative designs and functional aspects, see an earlier posting. )

One continuing point of experimentation remains the problem of creating the required temperatures for glass working - and sustaining them, within the furnace. Charcoal supplied with a gentle (!) air blast will certainly produce the required temperatures. One problem remains getting heat without excessive ash floating around (and sticking to the surface of the beads).

One continuing point of experimentation remains the problem of creating the required temperatures for glass working - and sustaining them, within the furnace. Charcoal supplied with a gentle (!) air blast will certainly produce the required temperatures. One problem remains getting heat without excessive ash floating around (and sticking to the surface of the beads).

One very successful addition to the interior of the furnace is to place a triangular diverter on the wall directly opposite the tuyere entry. Combined with a slight down angle to the tuyere, the net effect is a spiral pattern to the air flow and thus heat generation pattern. In this furnace, this circular pattern was clear in the way the charcoal was consumed.

Our current furnaces provide two possible working methods.

One is inside the furnace, through a port cut into the two long axis ends. For this furnace, Neil and I made slightly different cut angles and locations. I had kept to a more rectangular shape, and also cut the angle of the upper edge so it sloped upwards into the furnace. Generally this proved more effective in reducing some of the volume of hot air blast escaping towards the operator.

The second working area is inside the exhaust stack on the top of the furnace. Although a fresh charge of charcoal certainly provides enough heat here to bring the glass to working temperatures, the effective duration remains short. I think some additional refinements in the shape of the upper structure may improve the function of the stack area.

I worked as much as possible with the two types of tesseri (broken tiles) that Neil had purchased. By this point I (more or less) have managed to figure out how to take an irregular rectangle and wind it up to a roughly ball shape on a mandrill.

One important addition to our working method was developed by Neil over this session.

I can more or less manage a bead shape, even a bead with some decoration. Where it comes apart for me (literally) is in getting the finished bead off the mandrill! Neil had looked closely at a video of traditional workers and seen that they were able to tap off a still hot bead with a metal tool. After a number of failures, he discovered the key is in tapping the mandrill first, which seems to break up and loosen the applied clay separator / resist.

Although not shot at Goderich, there is a video clip on YouTube which shows an earlier experiment in this series.

For more information on the ongoing research into Norse glass beads and making, see the area on the DARC web site.

* Evil Nefarious Plan:

Is to introduce an element of archaeology, specifically Experimental Archaeology, into the fabric of the Festival. Next year marks 20 years for the Earth, Air Celtic Festival. I have tentative approval to build and operate a Celtic Iron Age, slag pit styled, iron smelting furnace as the public demonstration. In conjunction, my intended Celtic College offering will be 'Ancient Celtic Ironwork'. Students will work with a ground pit charcoal forge, bellows air and small block anvils. The likely projects will be small knives and spear points. On the last College session, they will aid in constructing the smelting furnace.

The day long firing of the furnace will be a major demonstration at the Festival, allowing for direct participation of students and others.

It will certainly be the very first time this type of furnace has ever been publicly presented in Canada, perhaps the first time in all of North America.

As part of my nefarious plans * for the Earth, Air Celtic Festival at Goderich, this year's demonstration was of a Viking Age glass bead making furnace.

Now, this is really the research project of Neil Peterson, fellow member of DARC. Neil has driven the project, and has applied his (considerable) analytical powers to understanding the related archaeological remains. Much of our work has been focused on the remains from Ribe, Denmark. One of the problems is that the actual bead making furnaces are only represented by a number of clay base plates, with none of the upper portions of the furnaces surviving. There are plentiful examples of scrap and waste glass from the making process, as well as a large number of various styles of completed beads. As glass is virtually indestructible, glass beads are a common grave find as well.

My contribution to the beginning of the project was as the 'fire guy', lending my forge experience to the problem of how to construct and operate a charcoal burning glass furnace. It quickly was apparent to me that I needed some direct experience with how glass bead making works! To that end I assembled a basic set of modern lamp working tools and supplies, and made roughly 150 beads - just to get the hang of it.

Neil had made the furnace up a week before and allowed it to air dry. The construction is made of our standard 50 / 50 mix of powdered clay / shredded dry horse manure. The base oval is roughly 30 x 60 cm, and it stands about 30 cm tall. This is the ninth rendition of the basic plan, which at this point is close to an effective layout in terms of heat generation and functional spaces. (For some discussion of alternative designs and functional aspects, see an earlier posting. )

One continuing point of experimentation remains the problem of creating the required temperatures for glass working - and sustaining them, within the furnace. Charcoal supplied with a gentle (!) air blast will certainly produce the required temperatures. One problem remains getting heat without excessive ash floating around (and sticking to the surface of the beads).

One continuing point of experimentation remains the problem of creating the required temperatures for glass working - and sustaining them, within the furnace. Charcoal supplied with a gentle (!) air blast will certainly produce the required temperatures. One problem remains getting heat without excessive ash floating around (and sticking to the surface of the beads).

One very successful addition to the interior of the furnace is to place a triangular diverter on the wall directly opposite the tuyere entry. Combined with a slight down angle to the tuyere, the net effect is a spiral pattern to the air flow and thus heat generation pattern. In this furnace, this circular pattern was clear in the way the charcoal was consumed.

Our current furnaces provide two possible working methods.

One is inside the furnace, through a port cut into the two long axis ends. For this furnace, Neil and I made slightly different cut angles and locations. I had kept to a more rectangular shape, and also cut the angle of the upper edge so it sloped upwards into the furnace. Generally this proved more effective in reducing some of the volume of hot air blast escaping towards the operator.

The second working area is inside the exhaust stack on the top of the furnace. Although a fresh charge of charcoal certainly provides enough heat here to bring the glass to working temperatures, the effective duration remains short. I think some additional refinements in the shape of the upper structure may improve the function of the stack area.

I worked as much as possible with the two types of tesseri (broken tiles) that Neil had purchased. By this point I (more or less) have managed to figure out how to take an irregular rectangle and wind it up to a roughly ball shape on a mandrill.

One important addition to our working method was developed by Neil over this session.

I can more or less manage a bead shape, even a bead with some decoration. Where it comes apart for me (literally) is in getting the finished bead off the mandrill! Neil had looked closely at a video of traditional workers and seen that they were able to tap off a still hot bead with a metal tool. After a number of failures, he discovered the key is in tapping the mandrill first, which seems to break up and loosen the applied clay separator / resist.

Although not shot at Goderich, there is a video clip on YouTube which shows an earlier experiment in this series.

For more information on the ongoing research into Norse glass beads and making, see the area on the DARC web site.

* Evil Nefarious Plan:

Is to introduce an element of archaeology, specifically Experimental Archaeology, into the fabric of the Festival. Next year marks 20 years for the Earth, Air Celtic Festival. I have tentative approval to build and operate a Celtic Iron Age, slag pit styled, iron smelting furnace as the public demonstration. In conjunction, my intended Celtic College offering will be 'Ancient Celtic Ironwork'. Students will work with a ground pit charcoal forge, bellows air and small block anvils. The likely projects will be small knives and spear points. On the last College session, they will aid in constructing the smelting furnace.

The day long firing of the furnace will be a major demonstration at the Festival, allowing for direct participation of students and others.

It will certainly be the very first time this type of furnace has ever been publicly presented in Canada, perhaps the first time in all of North America.

Wednesday, August 3, 2011

Viking Age Bead Making - at Goderich Celtic

On Saturday August 4 and Sunday 5, Neil Peterson (of DARC) and myself will be demonstrating Norse glass bead making techniques. The presentation will run roughly 1 PM - 4 PM, as part of the activities inside the Earth, Air Celtic Festival in Goderich Ontario.

For information and directions to the Festival web site.

Neil and I will be actually continuing our experimental work with Viking Age charcoal fired glass furnaces, based on artifact evidence largely from Ribe, Denmark. This has been an ongoing research and practical skills development project largely under Neil's leadership.

This will be a departure from what you have seen me do at the Festival in the past. In previous years, I have been illustrating proven techniques, which often have a historic basis, but generally I have been using modern tools. The focus is often towards the production of a finished object.

Here the stress is on experimental archaeology. The methods, even the exact tools, used by ancient Norse bead makers are not well represented by artifacts. The furnaces are represented only by flat base plates, no intact upper portions have ever been found. There is a LOT of guess work and trial & error involved!

So come watch us work - its sure to be an adventure. New discoveries can be made at any time!

So come watch us work - its sure to be an adventure. New discoveries can be made at any time!

Sunday, April 17, 2011

Bead Weekend

May 7 and 8 we will be building new bead furnaces for the summer, and spending some torch time practicing bead making skills on modern torches.

Gathering is up at Darrell's place. Please email for details

Neil

Gathering is up at Darrell's place. Please email for details

Neil

Subscribe to:

Posts (Atom)

Labels

- Cooking (1)

- events (39)

- experimental archaeology (16)

- glass (12)

- interpreting (4)

- iron smelting (11)

- media review (1)

- object (6)

- public presentations (23)

- research (3)

- textile (4)

- travel tales (19)

- Viking Age (27)

- Vinland (37)

DARC Links

DARC Calendar

| Date | Event |

|---|---|

| May 2-4, 2019 | EAC 11, Trento, IT* |

| May 9-12, 2019 | EXARC Session at ICMS, Kalamazoo, MI |

| May ??, 2019 | Open Workshop* |

| Jun 8-10, 2019 | Upper Canada Village Medieval Faire Presentation |

| Jun 29, 2019 | Smelt |

| Jul ??, 2019 | Bead Burn* |

| Aug ??, 2019 | Bead Burn* |

| Sep 6-8, 2019 | Althing (SCA Event) |

| Sep 15, 2019 | CAMELOT, Waterloo, ON |

| Oct 5, 2019 | Bogenschutzenfest, Kitchener, ON |

| Oct 12, 2019 | Smelt |

| Oct 25-26, 2019 | REARC, Williamsburg, VA |

| Nov 2, 2019 | Smelt |

| * | tentative |

Contributors

- Darrell Markewitz

- Karen Peterson

- Neil Peterson

- Vandy Simpson

- Contact Us: info@darkcompany.ca