Cross posted from Darrell's Hammered Out Bits

As part of my nefarious plans * for the

Earth, Air Celtic Festival at

Goderich, this year's demonstration was of a

Viking Age glass bead making furnace.

Now, this is really the research project of

Neil Peterson, fellow member of

DARC. Neil has driven the project, and has applied his (considerable)

analytical powers to understanding the related

archaeological remains. Much of our work has been focused on the remains from

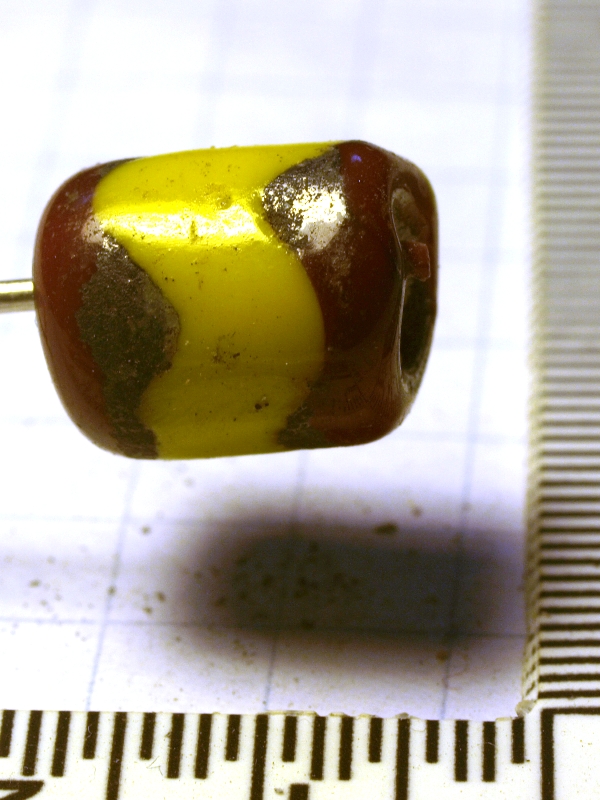

Ribe, Denmark. One of the problems is that the actual bead making furnaces are only represented by a number of clay base plates, with none of the upper portions of the furnaces surviving. There are plentiful examples of scrap and waste glass from the making process, as well as a large number of various styles of completed beads. As glass is virtually

indestructible, glass beads are a common grave find as well.

My contribution to the beginning of the project was as the 'fire guy', lending my forge

experience to the problem of how to construct and operate a charcoal burning glass furnace. It quickly was

apparent to me that I needed some direct experience with how glass bead making works! To that end I assembled a basic set of modern lamp working tools and supplies, and made roughly 150 beads - just to get the hang of it.

Neil had made the furnace up a week before and allowed it to air dry. The construction is made of our standard 50 / 50 mix of powdered clay / shredded dry horse manure. The base oval is roughly 30 x 60 cm, and it stands about 30 cm tall. This is the ninth rendition of the basic plan, which at this point is close to an effective layout in terms of heat generation and functional spaces. (For some discussion of alternative designs and functional aspects, see an

earlier posting. )

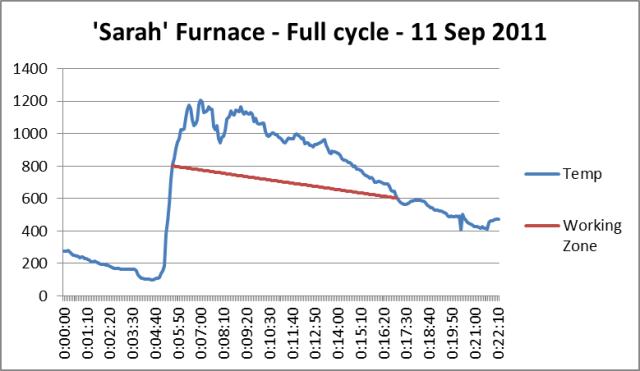

One continuing point of experimentation remains the problem of creating the required temperatures for glass working - and sustaining them, within the furnace. Charcoal supplied with a gentle (!) air blast will certainly produce the required temperatures. One problem remains getting heat without excessive ash floating around (and sticking to the surface of the beads).

One very successful addition to the interior of the furnace is to place a triangular

diverter on the wall directly opposite the

tuyere entry. Combined with a slight down angle to the

tuyere, the net effect is a spiral pattern to the air flow and thus heat generation pattern. In this furnace, this circular pattern was clear in the way the charcoal was consumed.

Our current furnaces provide two possible working methods.

One is inside the furnace, through a port cut into the two long axis ends. For this furnace, Neil and I made slightly different cut angles and locations. I had kept to a more rectangular shape, and also cut the angle of the upper edge so it sloped upwards into the furnace. Generally this proved more effective in reducing some of the volume of hot air blast escaping towards the operator.

The second working area is inside the exhaust stack on the top of the furnace. Although a fresh charge of charcoal certainly provides enough heat here to bring the glass to working temperatures, the effective duration remains short. I think some additional refinements in the shape of the upper structure may improve the function of the stack area.

I worked as much as possible with the two types of

tesseri (broken tiles) that Neil had purchased. By this point I (more or less) have managed to figure out how to take an irregular rectangle and wind it up to a roughly ball shape on a

mandrill.

One important addition to our working method was developed by Neil over this session.

I can more or less manage a bead shape, even a bead with some decoration. Where it comes apart for me (literally) is in getting the finished bead off the

mandrill! Neil had looked closely at a video of traditional workers and seen that they were able to tap off a still hot bead with a metal tool. After a number of failures, he discovered the key is in tapping the

mandrill first, which seems to break up and loosen the applied clay separator / resist.

Although not shot at

Goderich, there is a

video clip on YouTube which shows an earlier experiment in this series.

For more information on the ongoing research into Norse glass beads and making, see the

area on the DARC web site.

* Evil Nefarious Plan:

Is to introduce an element of archaeology, specifically Experimental Archaeology, into the fabric of the Festival. Next year marks 20 years for the Earth, Air Celtic Festival. I have tentative approval to build and operate a Celtic Iron Age, slag pit styled, iron smelting furnace as the public demonstration. In conjunction, my intended Celtic College offering will be 'Ancient Celtic Ironwork'. Students will work with a ground pit charcoal forge, bellows air and small block anvils. The likely projects will be small knives and spear points. On the last College session, they will aid in constructing the smelting furnace.

The day long firing of the furnace will be a major demonstration at the Festival, allowing for direct participation of students and others.

It will certainly be the very first time this type of furnace has ever been publicly presented in Canada, perhaps the first time in all of North America.